Process Plants

Sub-Categories

BioDiesel Plant. Construction started in 2006.

Item # PU-36

SOLD**BioDiesel Plant. Construction started in 2006. Plant to be built to Class A Standards. Designed capacity to be 7 million GPY when complete. All Licenses and Permits to produce Bio Diesel will Convey along with a 22 year lease on the property with option to extend. Cost to complete is approx. $1 million.**SOLD

BIODIESEL

7,000,000 GPY

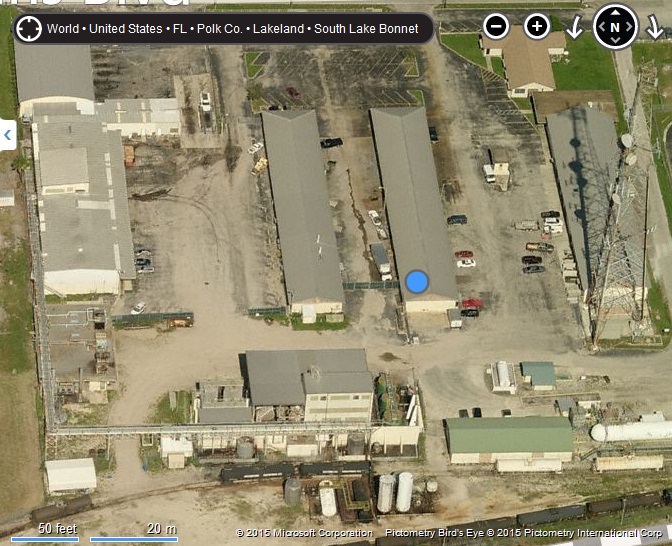

Biodiesel/Biofuels facility, has a current capability of about 10 million G/Y

Item # PU-34

***SOLD***Biodiesel/Biofuels facility, has a current capability of about 10 million G/Y, and can reasonably be expanded to about 18 million G/Y of production. Standard base catalyzed with Methanol addition. Plant includes methanol recovery and glycerine purification. The system is designed to handle a variety of feed-stocks. To date materials such as used vegetable oils, tallow, lard, corn oil, soybean oil, canola oil, mixed off-spec vegetable oils, and several vegetable oil/animal fat combinations have been successfully processed. Also located on site is a Glycerine Purification plant used to rum biodiesel grade glycerine by-product and purify it to technical and kosher grade glycerine. The Glycerine plant was capable of purifying 1,200,000 G/Y and is being sold separately. Quoted As Is Where Is. (GreenCat)

BIODIESEL/GLYCERINE PURIFICATION

10,000,000 GPY/1.2 M/GPY

Previous Specialty Chemical Manufacturing with Rail and Waste Water Treatment plant in Rock Hill

Item # PU-27

***SOLD***Previous Specialty Chemical Manufacturing with Rail and Waste Water Treatment plant in Rock Hill, South Carolina (Charlotte Area) For Sale. 50+ Acre site zoned Heavy Manufacturing. Rail Road Access. Site with complete waste water treatment plant added in the late 1990's at a cost of $5,000,000+. Treats up to 100,000 GPD. Main buildings on site with estimated sizes: 7800 sq.ft. Offices/change room/break room; 875 sq.ft. Laboratory; 1375 sq.ft maintenance area; 4800 sq.ft warehouse; 2625 sq.ft pole barn storage; 1665 sq.ft. warehouse; 2000 sq.ft warehouse. PROCESS EQUIPMENT NOT AVAILABLE and is mostly dismantled. Process equipment can be purchased separately. This has great potential for Waste Water Treatment Plant or Bio Diesel Plant.

Chemical Manufacturing and WASTEWATER TREATMENT

0

16,000 BPD Lube Hydrotreater

Item # PU-38

**SOLD**16,000 BPD Lube Hydrotreater, LHT at 3,000 psig. Unit was built by Fluor. The P&ID's of the unit are available upon request. The unit was used from 2000 to 2008, to run 20,000 BPD at 2,700 psig to make Gas Oil Feed for ethylene cracking and also used to make ULSD. The Lube Hydrotreater Reactor, R-024-01 is 8' diameter x 7', 3450 psig, Catalyst Volume: 2800 cu ft. The U1A, two drawings of the LHT Rx and the P&ID of the reactor portion of the LHT are available upon request. To summarize the materials of construction of the Rx: Shell thickness is 8.636" minimum, 9" ordered, Heads:5.757" Minimum, 6" and 6-1/2"ordered. Shell and heads are SA 387 Grade D, N and T, (which we assume means Normalized and heat Treated)63,000 psi Tensile Strength. The stainless weld overlay is 347 stainless, 3/16" thick. Design pressure is 3,450 psi at 850F Hydro tested at 5,134 psi. MAWP 3,477 at 825F; 3,505 MAWP at 800F; 2,977 MAWP at 900F. SOLD...NO LONGER AVAILABLE.

Hydrotreater

16,000 BPD

1400 T/D Methanol Plant for sale. Major equipment available.

Item # PU-43

**SOLD**1400 T/D Methanol Plant for sale. Major equipment available. The Following Equipment Remains For Sale: *Linde Syn Loop A, 720 T/D. *Purification Area, 1430 T/D. Systems are complete with pipe and equipment. Major Equipment for Sale: *Converter Linde Design installed in 1984, Item # 47008. *Steam Drum (integral to Linde Converter), Item # 4277. *Circulating Compressor w/ Steam Turbine Drive 5500 HP, Item # 48502/41502. *Crude MeOH Condenser 13,357 Sq.Ft., Item # 43010. *Crude Methanol Separator, Item # 47301. *Syn Gas Compressor w/ Steam turbine, 12,200 HP, Item # 48501/41501. Purification Area: *Topping Column, 9'dia. X 87' T/T, Item # 48001. *Refining Column, 10' dia. X 112'9" T/T, Item # 48002. *Finishing Column, 14'9"/13' dia. X 149'8" T/T, Item # 48003. Complete system with reboilers, condensers, drums, etc.

METHANOL PLANT

1400T/D

200 Ton/Day Nitric Acid Plant. Designed by Weatherby

Item # PU-45

used 200 Ton/Day Nitric Acid Plant. Designed by Weatherby. Built in 1972. Originally designed for 170 T/D. Major revamp in 1978/79. Shut down in mid 1990's. Absorber tower has 22 trays and is rated 120 PSI @ 200 Deg.F. NOX abatement unit added in 1978. DeLaval Air Compressor with tail gas expanders. Platinum filter was sent out in 2005 for recovery of platinum. Balance of equipment remains (Final inspection REQUIRED to confirm remaining equipment). Price is As is Where is.

NITIRIC ACID

200 T/DAY

30,000 BPD Oil Refinery. Consists of (2) 15,500 BPD refinerys

Item # PU-40

***SOLD*** 30,000 BPD Oil Refinery. Consists of (2) 15,500 BPD refinerys. Newer Alloy towers built in 2003 and 2005. Includes Naphtha Treater unit rated at 1935 BPD. Boscan Crude units and produced asphalt.

OIL REFINERY

30000 BPD

15,500 BPD Oil Refinery.

Item # PU-41

SOLD. 15,500 BPD Oil Refinery. (2) units available. Unit #1 has a newer alloy tower built in 2003 and Unit # 2 has a newer alloy tower built in 2005. Built for Boscan Crude and produced asphalt.

OIL REFINERY

15500BPD

UREA PLANT FOR SALE. Rated 700 TPD

Item # PU-29

**SOLD**UREA PLANT FOR SALE. Rated 700 TPD. Originally designed to produce 600 short tons per day of Urea in the form of Granules. Constructed by C&I Girdler in 1973/74. The synthesis and recovery sections utilize the Snam-progetti Process Design. The finishing section employs the C&I Gridler-Cominco Spherodizer Granulation Process. Total Recycle Design. The Granulation Process was shut down in 1991, but the plant continued producing 700T/D of liquid Urea. The remainder of the plant was run until 2003 producing liquid Urea. Unit is match marked, dismantled and ready to load. Loading cost is additional. SOLD SOLD

UREA

700 TPD

Urea Spherodizer Granulation Plant for sale

Item # PU-26

Urea Spherodizer Granulation Plant. Granulation Section Only. C&I Girdler Semi-carbon design. 1000 T/D design in (2) trains. 1500 T/D maximum recorded production. Major equipment includes:(2) Each Spherodizer Granulation Systems. 14' dia. X 50'lgth. with conveyors and screens.(2) Each Scrubber Systems. Stainless steel bodies with 60,000 ACFM fans and ductwork. (1) Refrigeration system with 1320 Ton Ammonia compressor. (1) Train was sold, (2) trains Left.

Urea Granulation Plant

1000

HIGH VACUUM Ethanol DISTILLATION System for sale

Item # PU-37

***SOLD***HIGH TEMP / HIGH VACUUM DISTILLATION SYSTEM Thin Film for Molecular Separation including Solvent Recovery. Multiple use Thin Film distillation plus high temperature system: Operational temperature up to ~325 Deg.C (620 Deg.F) at 1.0mm vacuum. Last used for Ethanol Distillation for Cannabis oil. This is a "state-of-the-art" chemical processing / distillation / separation / polymerization / purification / chemical reaction production pilot plant. There is literally very little that this system is not designed to accomplish when it comes to any chemical processing need. Originally, it was a ~$1.45MM unit as installed in late 2009 - early 2010. Only used to evaporate water from inert solids powder, it has been used very sparingly since then. It is in very good working order, and is designed for easy dis-assembly and re-assembly. Excellent pilot / production system for most applications including: A) Rm or high temp/vac distillations B) Polymerizations C) Pharm. synthesis & purifications D) Liquid-solids separations, E) High-temp / high-vac reactions. F) Liquid - liquid separations Efficiently separates multiple liquids with different boiling / vaporization properties. Also separates single or multiple liquids from most types of suspended solids. Horizontal thin film wiper chamber has approx 1/4" or less clearance. Rated up to 400 gallons an hour. It is legally in a C1 Div 2 room and has been inspected. Only explosion proof equipment, fixtures etc. are allowed to be in a C1D1 or C1D2 room by code. Sold AIWI. Last client used ~4 guys with 4 days to disassemble and loaded all onto 1 lowboy trailer.

VACUUM DISTILLATION SYSTEM

.JPG)

.JPG)

.jpg)

.JPG)